- Messages

- 17,233

- Location

- Maryland

I received the following update from Ms. Elena Poletti Director of the Museo dell’Arte del Cappello di Ghiffa regarding Panizza Velour production. Interesting that Panizza didn't make Velour finishes until after WWII which I suspected (also not shown in the 1951 Panizza Production film).

"Finally I succeed in interviewing one of the hatters about the brushing machine.

Unfortunately they do not have many information but:

- They think that the machine was made by the factory MEZZERA which was in Milan and was the main suppliers of machinery for Panizza.

- It is of the Seventies, not very old

- Panizza started to make velour finishes after WWII, the best period for that finishing were the Sixties and Seventies

- At the memory of the last hatters they did not hand-brush, because the velour finishing started in pretty recent times when all the working process was already made by machines."

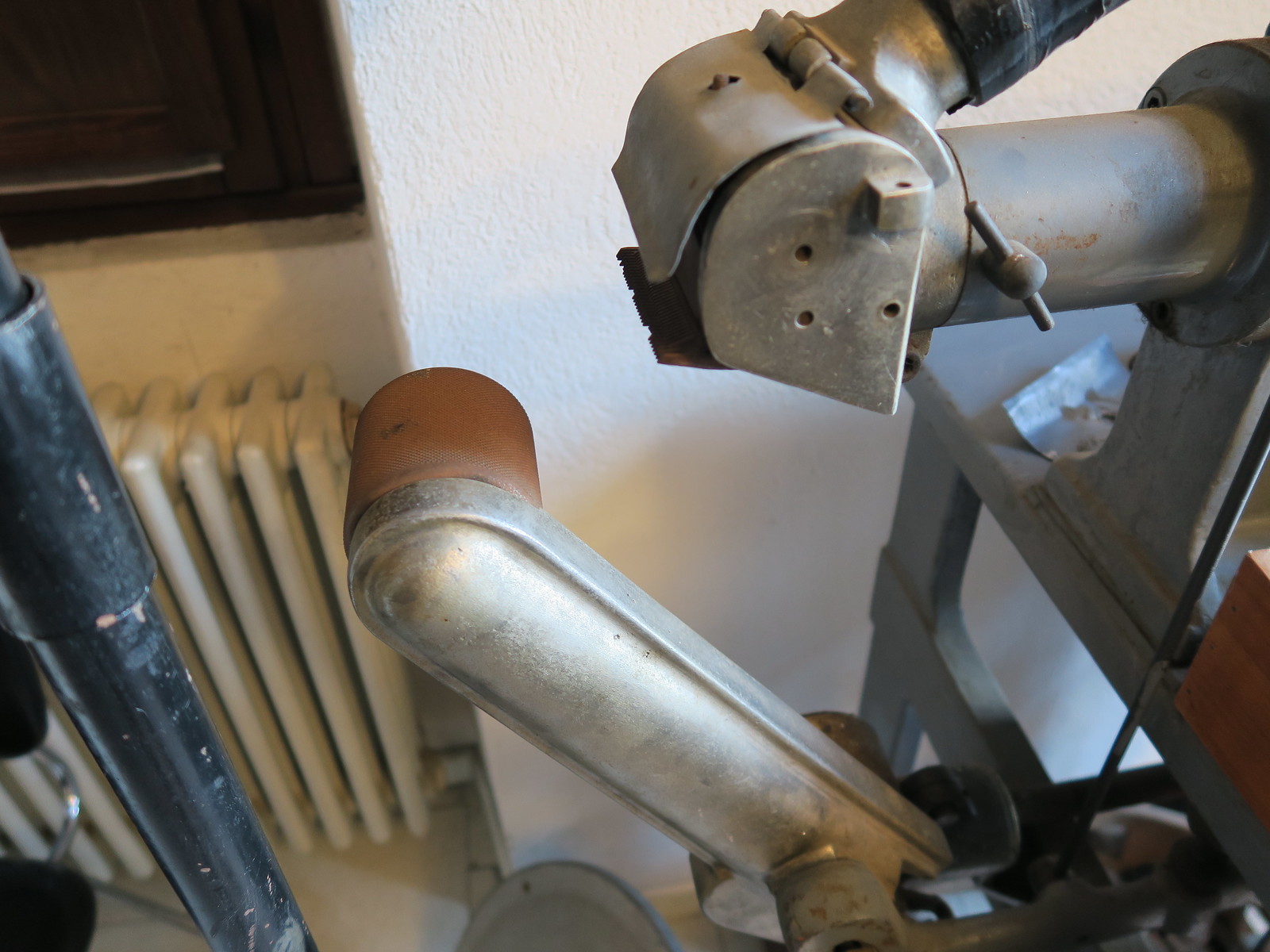

Velour Auto-Brushing Machine (probably made by MEZZERA in the 1970s) used in Panizza Ghiffa Factory. This brushing takes place during felting. This process was originally done manually. Supposedly the automated process never matched the manual process but it's apparent that some manual brushing took place once the process was automated. You can't have Real Velour without this Hot Wet Brushing taking place.

"Finally I succeed in interviewing one of the hatters about the brushing machine.

Unfortunately they do not have many information but:

- They think that the machine was made by the factory MEZZERA which was in Milan and was the main suppliers of machinery for Panizza.

- It is of the Seventies, not very old

- Panizza started to make velour finishes after WWII, the best period for that finishing were the Sixties and Seventies

- At the memory of the last hatters they did not hand-brush, because the velour finishing started in pretty recent times when all the working process was already made by machines."

Velour Auto-Brushing Machine (probably made by MEZZERA in the 1970s) used in Panizza Ghiffa Factory. This brushing takes place during felting. This process was originally done manually. Supposedly the automated process never matched the manual process but it's apparent that some manual brushing took place once the process was automated. You can't have Real Velour without this Hot Wet Brushing taking place.

Last edited: