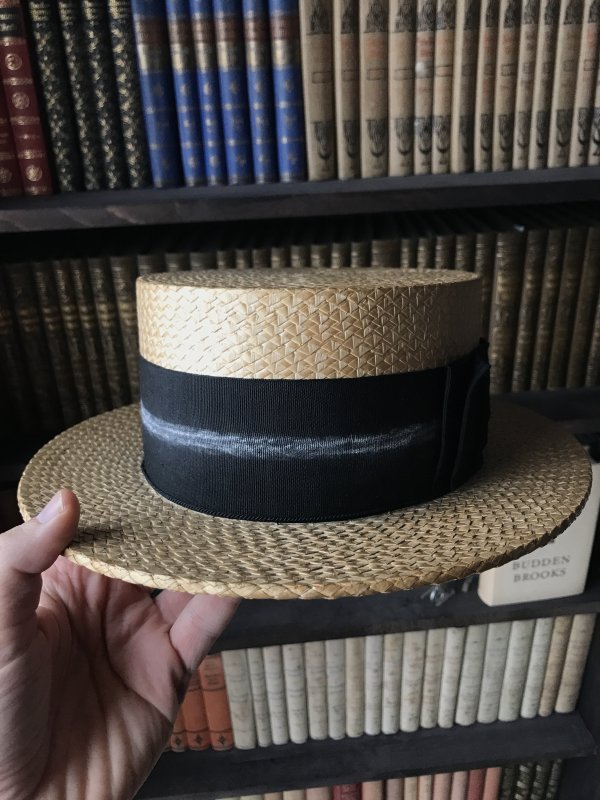

It's been a while since anything was posted in this thread, but here's one. Pascal&Cie bowler hat. Size 56 with the brim at 5,5cm and the crown at 12cm. Runs somewhat small for its size, but a well made hat.

Pascal&Cie was located in the Rue du moulin in Bruxelles and that's all I can find about the maker. The inside of the sweatband has a "marque deposée" stamped on it with the letters Th. C.C.V.

It was sold by Edw. Jorgensen in Odense, Denmark. Steve @Steve1857, who found this hat, couldn't find more information about the retailer either, so it is a bit of a mystery.

Pascal&Cie was located in the Rue du moulin in Bruxelles and that's all I can find about the maker. The inside of the sweatband has a "marque deposée" stamped on it with the letters Th. C.C.V.

It was sold by Edw. Jorgensen in Odense, Denmark. Steve @Steve1857, who found this hat, couldn't find more information about the retailer either, so it is a bit of a mystery.