Fifty150

One Too Many

- Messages

- 1,852

- Location

- The Barbary Coast

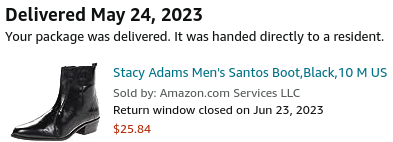

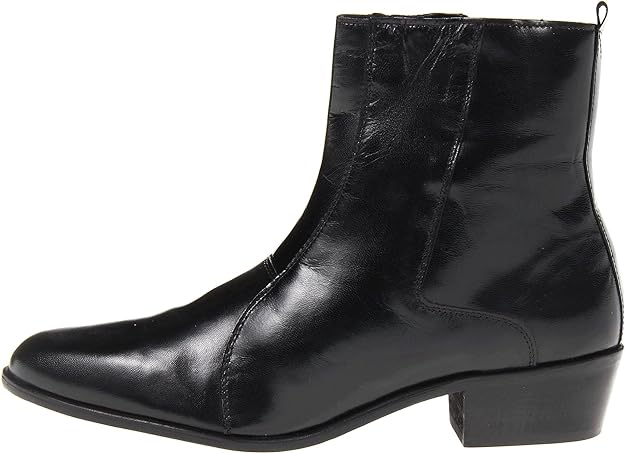

I went to a local cobbler to get a quote on resoling my Stacy Adams Madison boots. Heels were worn down. The soles are worn down. Now was a good time to fix them, before they got worse and needed more work.

The quote was for "$$$". The shoe repair guy said that he would grind off and sand down the leather sole, then glue on a piece of rubber, and replace the heel block. He shows me a plastic heel block which was stamped "Taiwan", and a sheet of rubber which is usually used as a "sole saver". I could literally save money by buying another pair. I blurted out, "that's a hack job!"

After thinking it over, I decided to do it myself. I decided on Vibram Christy soles. I have other boots which came with Christy soles, and I really like them.

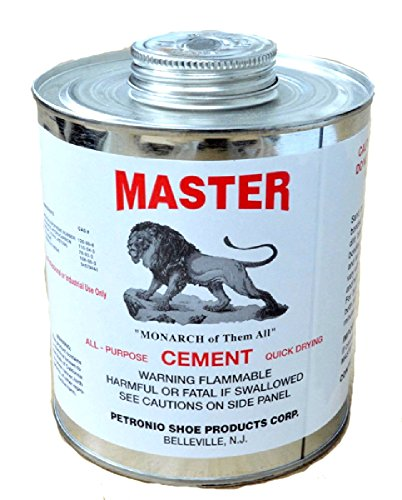

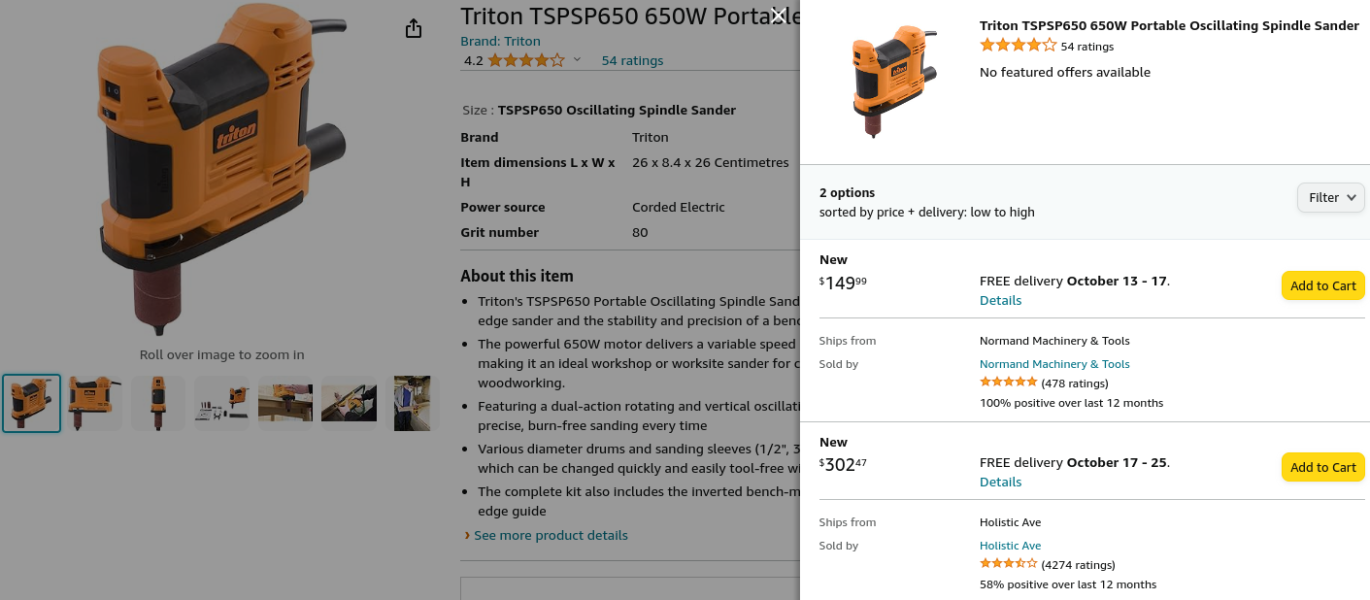

I removed the heel, cut off the nails, and sanded everything down. Next step is glueing on the new soles. How hard can this be?

The quote was for "$$$". The shoe repair guy said that he would grind off and sand down the leather sole, then glue on a piece of rubber, and replace the heel block. He shows me a plastic heel block which was stamped "Taiwan", and a sheet of rubber which is usually used as a "sole saver". I could literally save money by buying another pair. I blurted out, "that's a hack job!"

After thinking it over, I decided to do it myself. I decided on Vibram Christy soles. I have other boots which came with Christy soles, and I really like them.

I removed the heel, cut off the nails, and sanded everything down. Next step is glueing on the new soles. How hard can this be?