Yesteryear

One of the Regulars

- Messages

- 240

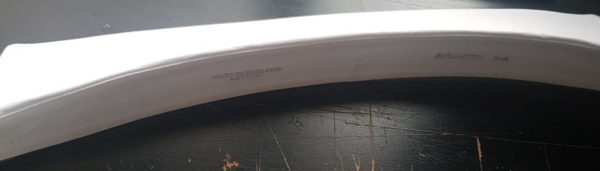

This thread is designed to be a collective resource for detachable collar starching. Feel free to share any methods, tutorials, videos, and tricks you've found helpful while making the perfect starched collar.

Let's get started, here is a short film from 1932 showing collars being starched at the Castlebank Laundry in Scotland:

[video=youtube;UJp3V9TL8xs]http://www.youtube.com/watch?v=UJp3V9TL8xs[/video]

Let's get started, here is a short film from 1932 showing collars being starched at the Castlebank Laundry in Scotland:

[video=youtube;UJp3V9TL8xs]http://www.youtube.com/watch?v=UJp3V9TL8xs[/video]