- Messages

- 17,280

- Location

- Maryland

Yes that is what I saw at TONAK. They use a wooden block to make the open crown, finish the felt and use metal blocks to form the complete hat.

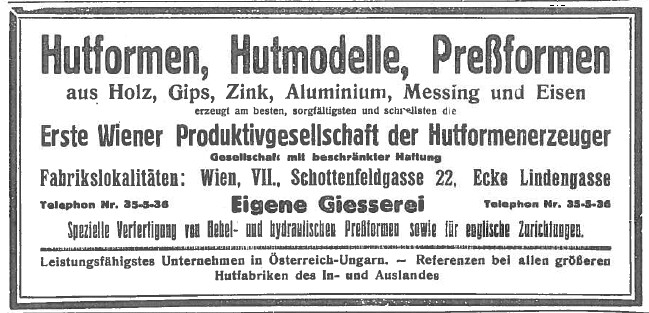

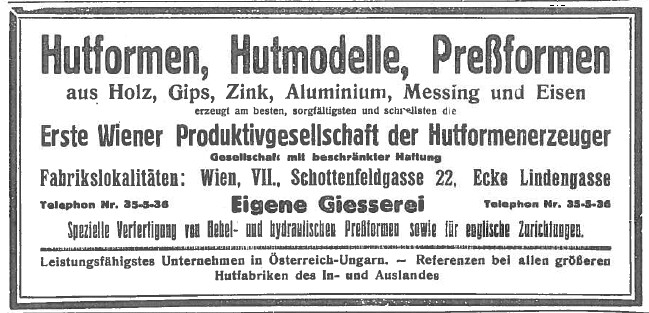

Metal blocks are mentioned in early 20th Century German and Austrian hat trade publications. I assume it was the same in America. Here is an Austrian ad from December 1912 (see Hutformen). By the way Holz is wood in German.

1928

1930

Metal blocks are mentioned in early 20th Century German and Austrian hat trade publications. I assume it was the same in America. Here is an Austrian ad from December 1912 (see Hutformen). By the way Holz is wood in German.

1928

1930

Last edited: