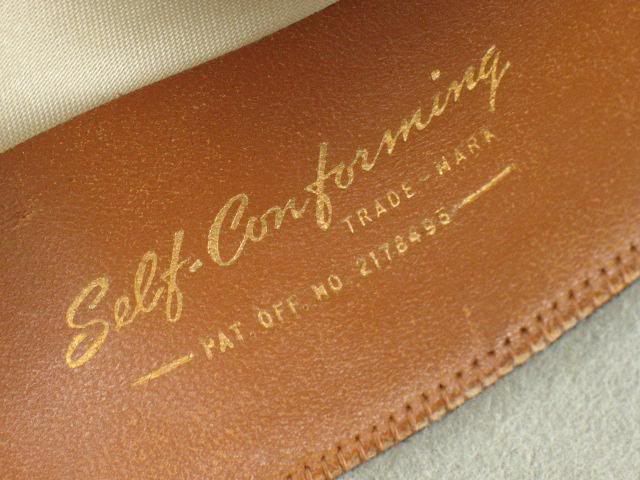

Gilgamark

A-List Customer

- Messages

- 306

- Location

- Nashville, TN

Jabos said:Beautiful Adam G-Mark. I can select the size the pic will be before I upload to Photobucket. What a BIN pick up for you.

Thanks. I'll pick a smaller size from here on. :eusa_doh: :eusa_doh: