ChicagoWayVito

Practically Family

- Messages

- 699

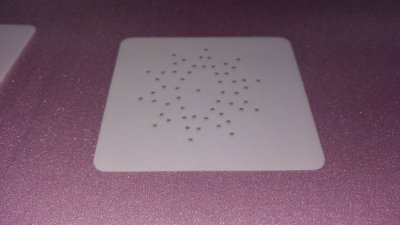

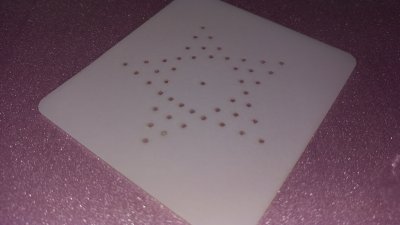

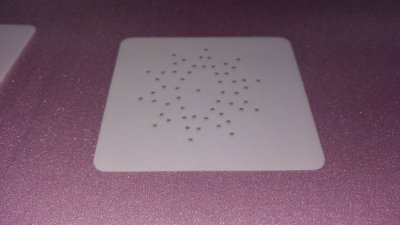

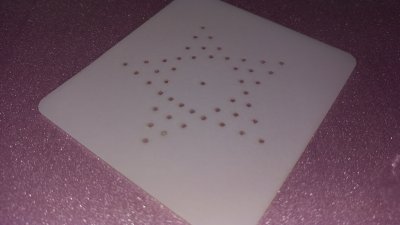

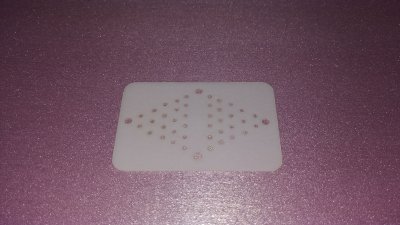

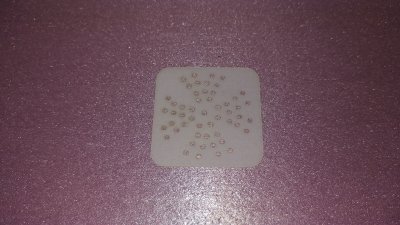

I just created these two templates and cut them out on a laser cutter. I hope to try them out soon. The thought is that I could mark the felt with powered chalk or a disappearing fabric marker and only the hole marks would be left behind. Just need to get a small leather punch and try it out. The actual designs measure about 1.5" squared. I will post back here after I have actually used them. The pink surface was just some insulation foam to help show the patterns.